| Model | HZ450DJK |

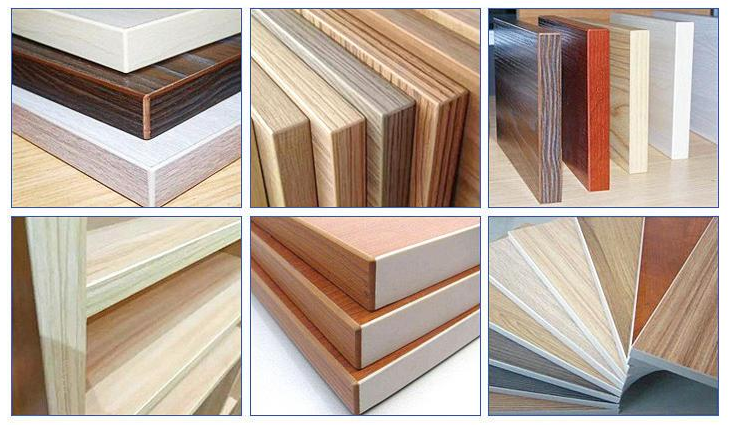

| Edgeband thickness | 0.4-3mm |

| Edgeband width | 10-60mm |

| Panel min. width | 80mm |

| Feeding speed | 12-20m/min |

| Air pressure | 0.8Mpa |

| Total power | 17.4kw |

| Overall dimension | 6800X1100X1600mm |

| Weight | 2800kg |

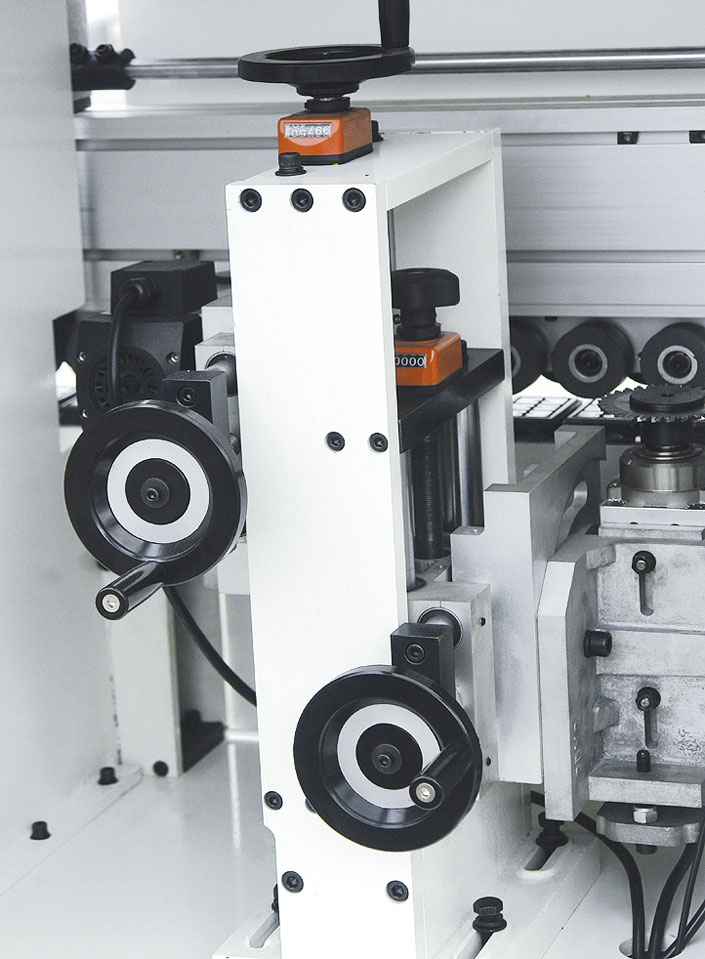

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped9. Hogging: Make a straight groove on the bottom or top of boards .

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

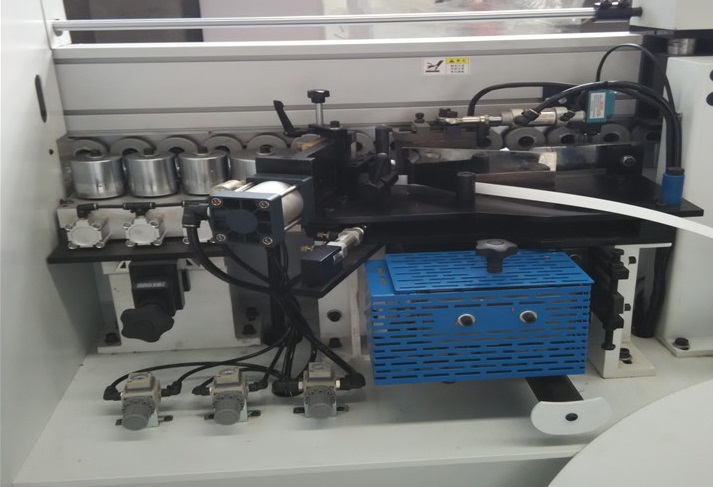

7. Corner trimming group: It makes corner of panels smooth and beautiful.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

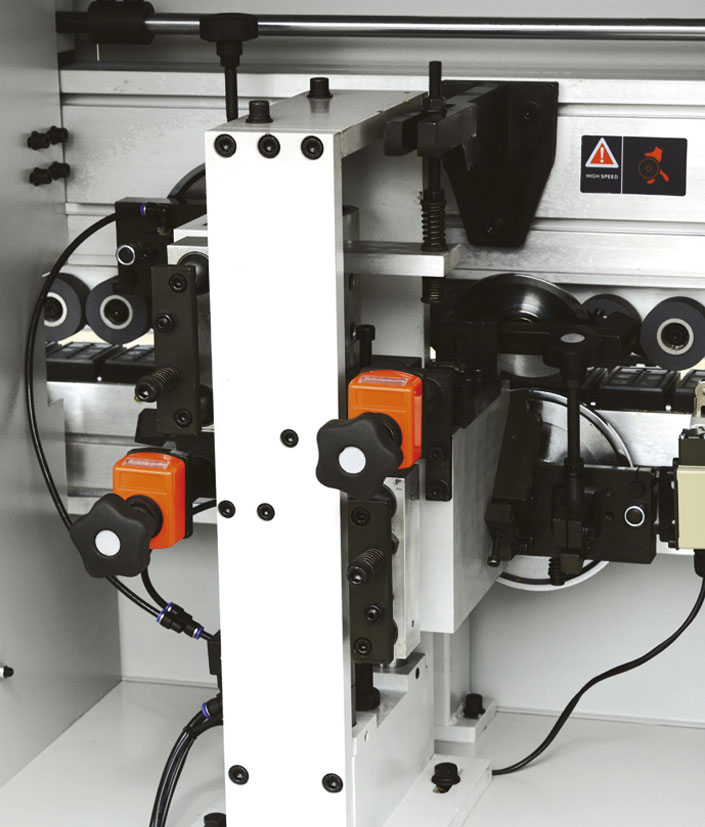

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors. 2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

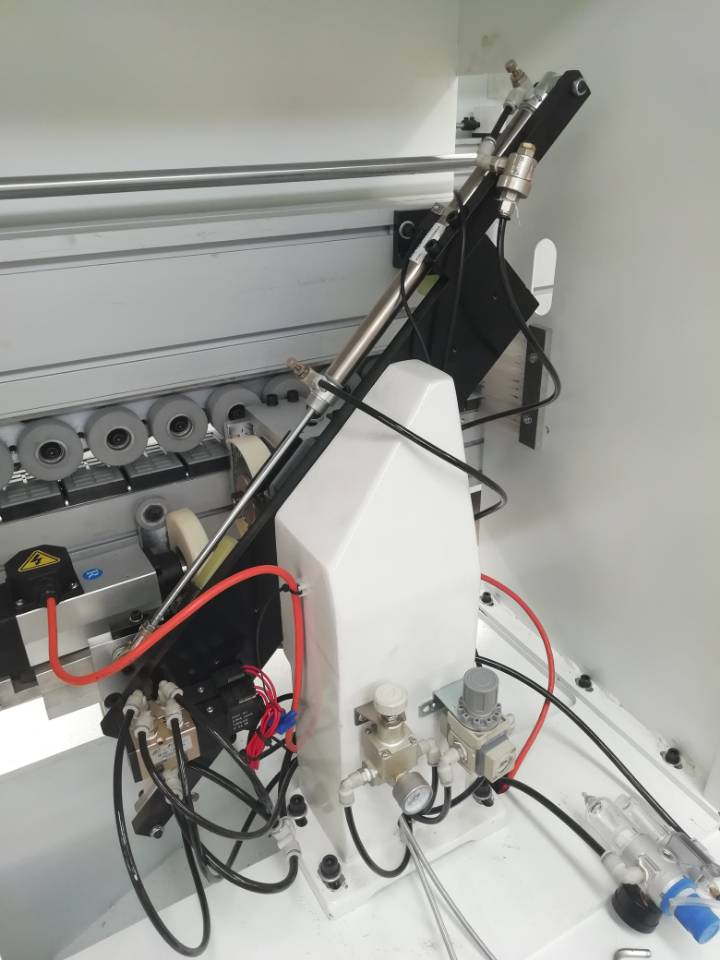

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly. 4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.